Downloads

- Marine bronze shells

- Shell to shell sealing with 2 O-rings in coupling interface

- Cable termination with pressure gland or with overmolding

- Integrated endshell

- Shell polarization keys and scoop proof

Key features and benefits

Description

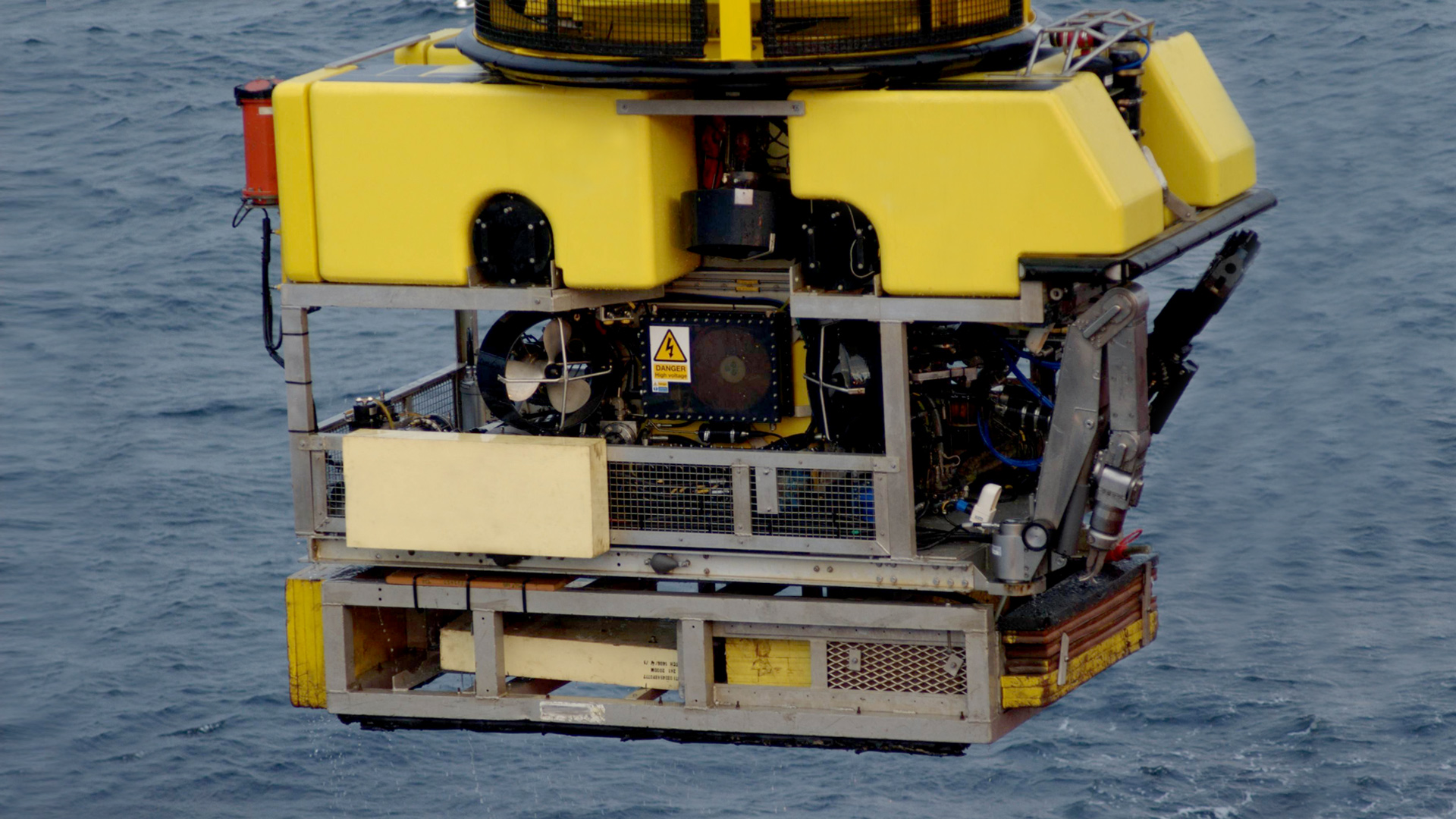

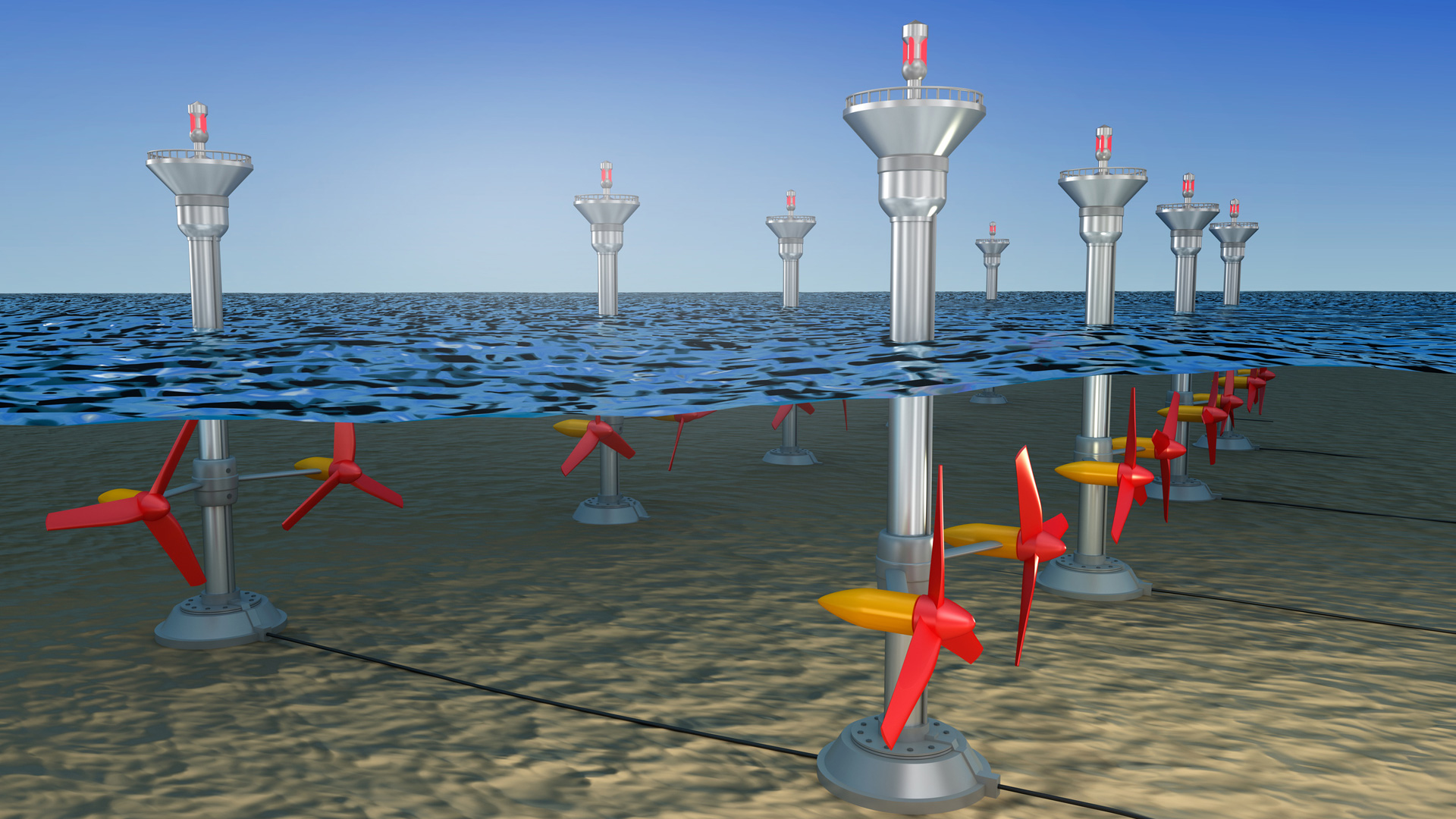

The M Series connectors meet the highest standards of safety for deep immersion. It is currently used in many applications: from oil and gas industry service to renewable energy generation systems and military submarines.

- Marine bronze shells: high corrosion resistance and high biological fouling resistance

- Shell to shell sealing with 2 O-rings in coupling interface. No stress on O-rings by conical coupling interface. Marine bronze coupling ring: reliable watertightness regardless of the pressure (low or high). Easy to mate and unmate even with high contact density layouts.

- Cable termination with pressure gland or with overmolding (see catalogue for other types of cable termination like PBOF or double watertightness). High pressure resistance and high cable mechanical retention

- Integrated endshell: extreme resistance to pull out or transverse forces and to vibrations and shocks

- Shell polarization keys and scoop proof: makes blind mating possible. Increased robustness.

Technical Data

- Salt spray: 10 x (24h + 24h) alternate salt spray according to EN60068-2-11. 500h continuous salt spray according to NFC93422.

- Operating temperature range: -20°C to + 70°C

- Mated pressure withstand

- Pressure gland cable termination: Operating pressure up to 100 bar. Tested at 200 bar.

- Overmolded cable termination: operating pressure up to 300 bar. Test according to customer specification.

Examples of application field

M connectors are used in many applications: from oil and gas industry service to renewable energy generation sustems and military submarines.